Laser Alumina Reduction Group

Laser-induced reduction of alumina from moon resources

Introduction

Welcome to our research group! This website introduces the Lunar Resources Reduction Group within the Komurasaki Laboratory at the University of Tokyo. Our work focuses on the high-temperature processing of lunar regolith and the development of advanced aluminum-oxide reduction techniques using laser-driven thermal and plasma phenomena. These studies aim to establish foundational technologies for in-situ resource utilization (ISRU) and sustainable materials production on the lunar surface. |

Background

|

Plans for constructing lunar bases are currently being developed by space agencies and research institutions around the world [1]. In Japan as well, JAXA has outlined a long-term vision for establishing a lunar base within the next two decades as part of its space exploration roadmap [2]. The utilization of lunar resources is considered essential for achieving sustainable human activity on the Moon. By extracting metals and oxygen directly from lunar regolith — rather than transporting them from Earth — it becomes possible to significantly reduce both cost and logistical burden. This concept is known as In Situ Resource Utilization (ISRU). Our research team is working on a laser-based reduction method for alumina, which constitutes up to 25% of lunar regolith in the highland regions [3]. The laser-based process is functionally interchangeable with solar energy, which is readily available on the lunar surface and can be directly harnessed for the production of aluminum and oxygen without reliance on terrestrial supply chains. Through this approach, we aim to contribute to future ISRU-based systems for sustainable lunar operations. |

Mechanism of Reduction

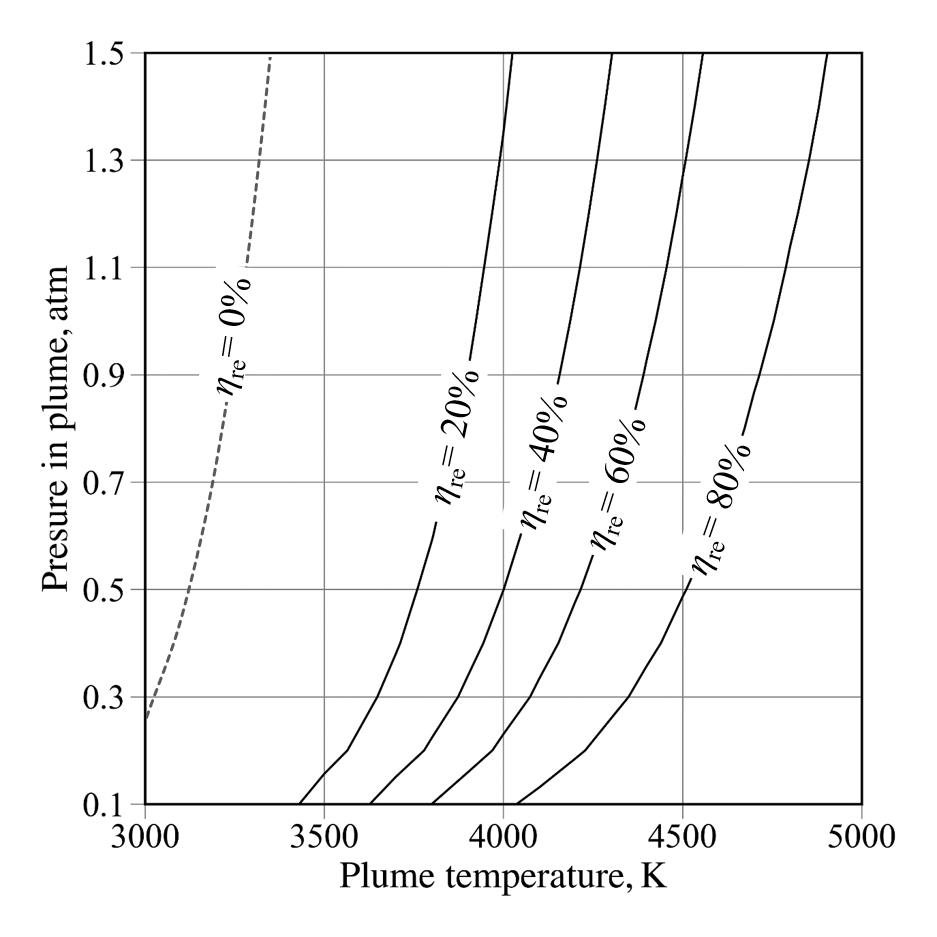

The direction in which an oxidation–reduction reaction proceeds is determined by the oxygen partial pressure and the temperature. The figure on the right shows a reduction-rate map under the assumption that the plume is in thermodynamic equilibrium. The reduction rate represents the fraction of aluminum in the plume that exists as elemental aluminum atoms. The horizontal axis indicates temperature, and the vertical axis indicates pressure. From the graph, it can be seen that the reduction rate increases at higher temperatures and lower pressures. At present, a reduction rate of 32% has been achieved at 4000 K and 1 atm using the laser ablation method. |

|

Reduction Method Using Laser Sustained Plasma

|

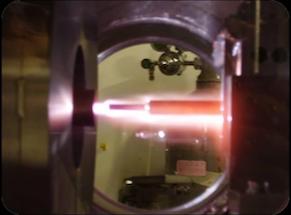

We had been researching a method of reducing powdery alumina using heating by the plasma generated by the laser.

This plasma is called LSP, which stands for Laser Sustained Plasma.

The temperature of the central area of LSP is about 15000 ℃ and it heats alumina at this quite high temperature.

|

Reduction Method Using Laser Ablation

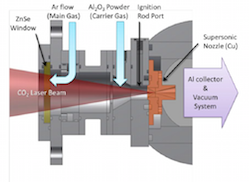

We are currently investigating a laser-ablation–based method for reducing aluminum oxide.

In this approach, a high-density laser beam is focused directly onto solid alumina, rapidly heating it to an extremely high temperature. Because the material is heated directly by the laser—without using an LSP—this technique is expected to offer significantly higher reduction efficiency.

|

|

Regolith Refinement Using Selective Vaporization

|

Before aluminum oxide can be thermally reduced on the lunar surface, raw regolith must first be refined into an alumina-rich feedstock. Lunar regolith contains a wide distribution of oxides—such as Na2O, K2O, FeO, MgO, CaO, and SiO2—many of which exhibit significantly higher volatility than Al2O3 at elevated temperatures. In our selective vaporization approach, a high-intensity laser is used to heat regolith to extreme temperatures, preferentially vaporizing the more volatile oxide components (e.g., Na2O, K2O, and SiO2). By thermally removing these volatile oxides, the remaining solid residue becomes progressively enriched in aluminum oxide. This refinement pathway enables the production of higher-purity alumina feedstocks suitable for the thermal reduction techniques described above. Selective vaporization therefore serves as a critical upstream step in an integrated ISRU process chain—linking regolith beneficiation with high-temperature alumina reduction for sustainable in-situ production of aluminum and oxygen on the lunar surface. |

Test Chamber

|

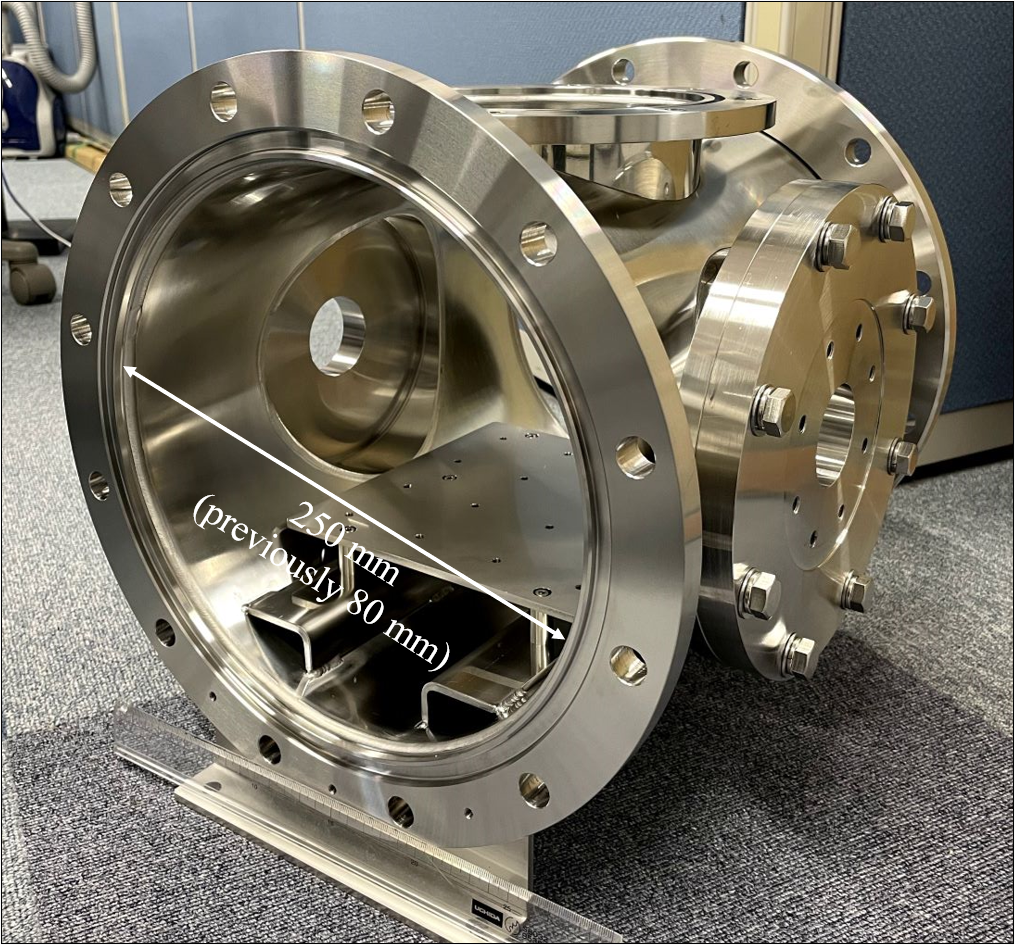

The laser passes the window on the right side in the photo to heat alumina placed in the chamber.

|

|

This new chamber was set in 2021.

|

High-Power CW Laser

|

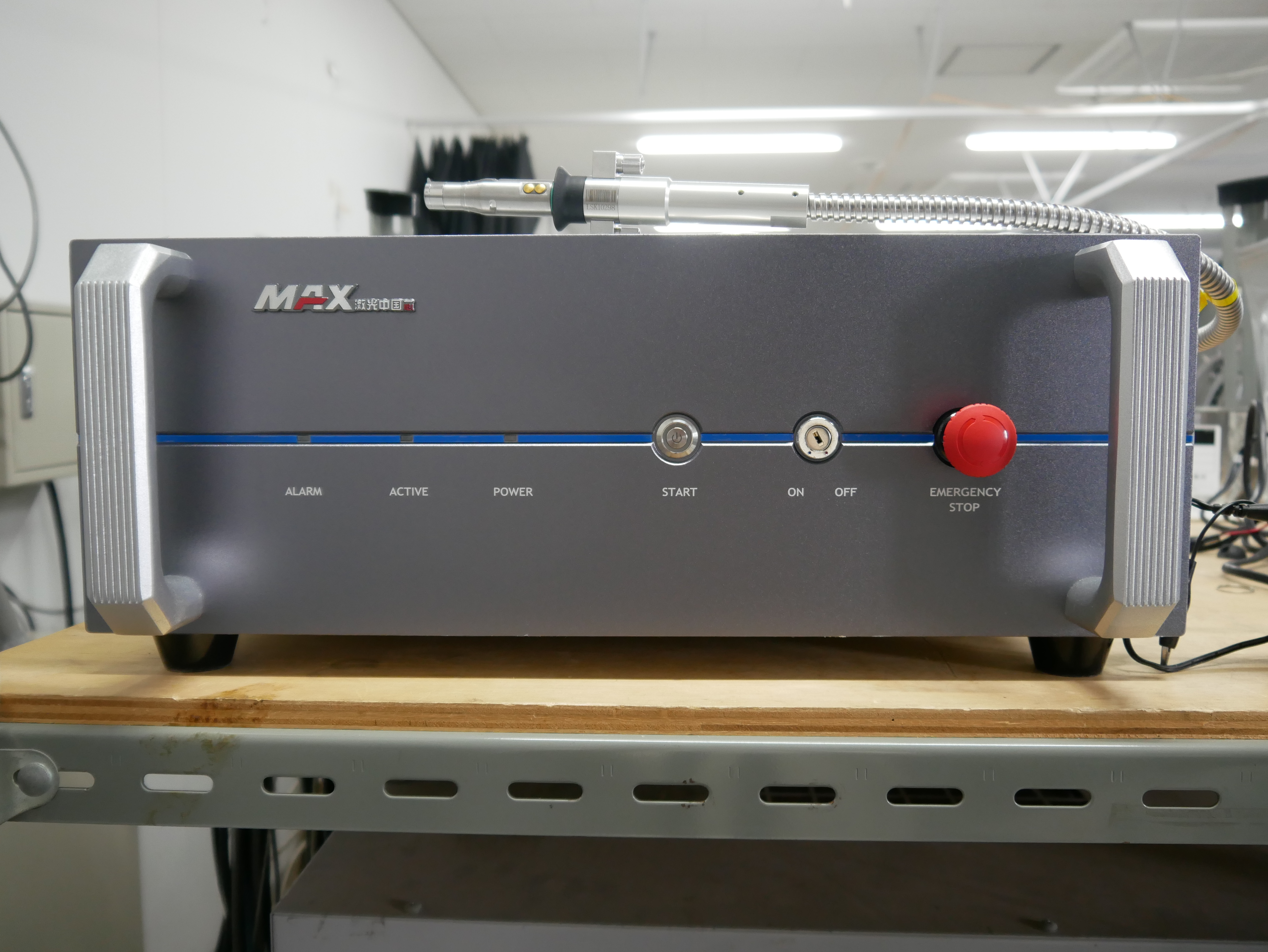

In 2022, we installed a new fiber laser with a rated output of 1.5 kW. This addition enables high-pressure laser ablation experiments that were previously impossible with CO2 lasers due to plasma formation in their wavelength band. |

Journal Paper

International Conference

Domestic conference in Japan

Master thesis

|

2019

|

|

アルミナレーザー還元における生成アルミニウムの不均一凝縮核生成による回収

|

|

2018

|

|

レーザーアブレーションアルミナ還元手法における試料予加熱による還元率向上 |

2011 |

レーザー維持プラズマを用いたアルミナ還元技術に関する研究 |

Bachelor thesis

2020 |

|

レーザー加熱を⽤いたアルミナ還元におけるアルミニウム粒析出・蒸着現象の研究

|

|

2019 |

|

ジルコニア混合によるレーザーアルミナ還元率向上

|

|

2017 |

|

アルミナのレーザーアブレーションにより生ずるAl-O系プルームの回収板付着実験 |

|

2016 |

|

月資源利用を目指したレーザーによるアルミナアブレーション還元実験 |

|

2015 |

|

レーザー維持プラズマによるアルミナアブレーションガスの還元実験 |

|

2014 |

|

CO2連続レーザーによるアブレーション実験 |

|

2013 |

|

レーザーアブレーションによるアルミナ還元の基礎研究 |

Joint Group

KAKENHI

Aluminum Energy Cycle

|

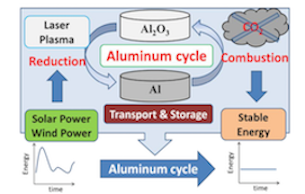

Alumina reduction using laser is useful not only on the moon but also on the earth.

|

CW Laser Propulsion

We used to research CW laser propulsion.

|

|

Plasma Wind Tunnel

We also researched application of the exhaust jet of the laser propulsion unit for a wind tunnel.

|

|