What are difficulties of Solid Propellant PPT?

Although PPT is expected to applied to microsatellites due to its simplicity and compactness, there are some difficulties in Solid Propellant PPT.

Following difficulties are concerned for PPT using solid propellant (PTFE) for its propellant.

1. Excessive propellant supply from the PTFE surface after the main discharge (late time ablation).

2. Uneven propellant consumption on the PTFE surface (uneven propellant consumption).

3. Contamination of other parts of the satellite by carbon or fluorine in the exhaust gas (contamination).

Problem 1 is considered to be one of the main reasons degrading the thrust efficiency of PPT. Propellant supplied after the main discharge are not accelerated to high velocity because they do not experience the electric acceleration sufficiently.

Problem 2 is caused by the passive propellant supply function of solid propellant PPT. Uneven propellant surface can decay the thruster performance in long-term missions.

Problem 3 doesn't affect the thrust efficiency, but this problem can be crucial for real applications. Black carbon and chemically reactive fluorine can cause unexpected effects on other parts, or other satellites in constellation missions.

Liquid Propellant PPT

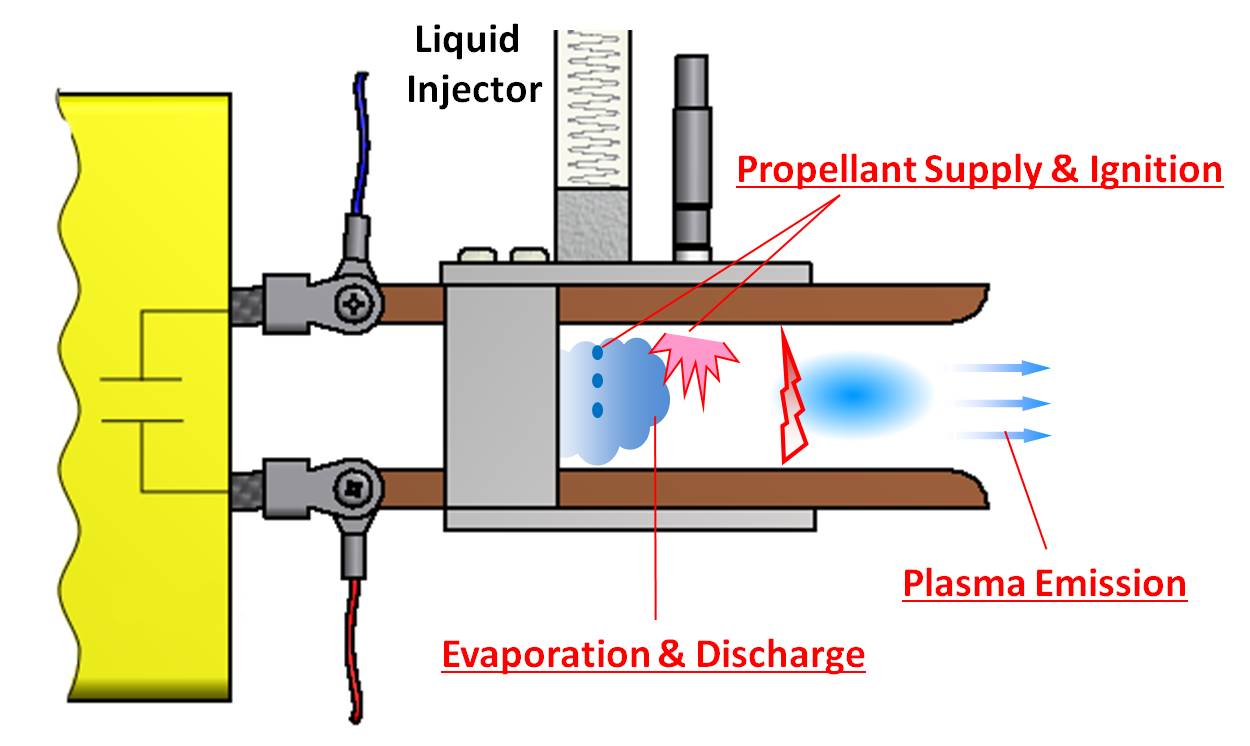

In order to solve these difficulties, we are suggesting a liquid propellant PPT (LPPT) utilizing water for its propellant. The following picutre shows the concept of LPPT.

Liquid Propellant Pulsed Plasma Thruster

The big difference between solid propellant PPT and LPPT is propellant supply function. LPPT pour an optimal amount of liquid between the electrodes, and fire the igniter with slight delay from injector.

Accorgin to this active propellant supply function, LPPT has solutions for the difficulties mentioned above.

1. Due to its active propellant supply, LPPT avoid the problem of excessive propellant supply by late time ablation.

2. The probem of uneven propellant supply can be solved as well.

3. Water doesn't affect other parts of the satellites.

As described above, LPPT can solve the crucial problems of solid propellant PPT. However, there are also some difficulties in LPPT like management of liquid in vacuum condition, design of an injector with a good responce,

and evaporation of water for ionization. We are trying to find solutions for these problems of LPPT.

Develpment of High Performance PPT for Lunar Mission BW-1

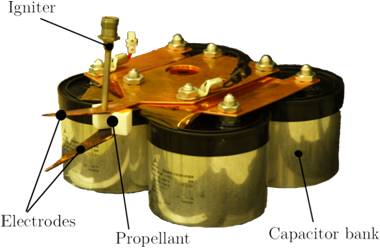

Researches of a high performance solid propellant PPT (ADD SIMP-LEX) are conducted in Kashiwa PPT team for the application of ADD SIMP-LEX to the main thruster system of Lunar Mission BW-1.

This thruster has been developed in IRS (Institute of Space Systems), and plasma diagnostics and elucidation of physics in PPT are mainly conducted in out laboratory.

This thruster is optimized in terms of discharge circuit parameters and electrode shape in experimental method, and achieved the specific impulse of about 2700s, which is relatively high for its energy level.

The characteristics of this thruster are flared triangular electrodes, multiple bank capacitors, and side-fed configration.

Our group welcomes international students. We daily have active discussions on researches in English, while the international students train their Japanese skill.

If you are thinking about the research experience in our laboratoty, please contact us!

|

|

| ADD SIMP-LEX | Lunar Mission BW-1 |